| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

矩形真空清洗炉 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

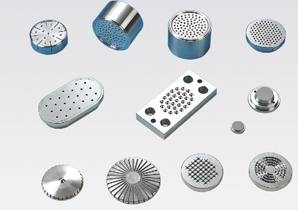

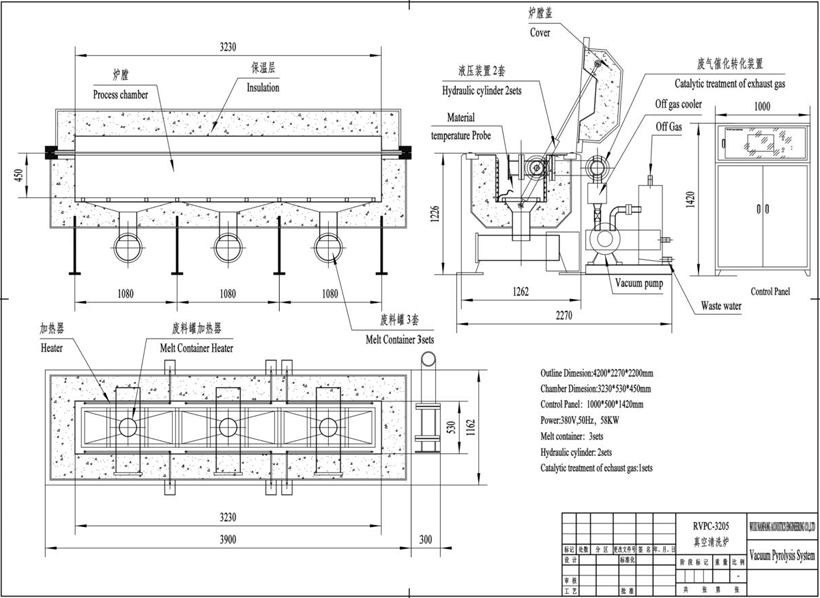

Rectangular Vacuum Pyrolysis Cleaning Device: (RVPC-series) Cleaning Objects: Spin-pack of PET、PA6/66 project; Especially the cleaning of non-woven spinneret As well as larger circular workpiece Cleaning Objects:    Specifications:

§1.Configuration Take Device Mode: RVPC-3205 as example Cleaning ability :3000×200mm spin-pack, 2 pcs can be washed at same time. §2. Cleaning principle The spin packs to be cleaned are placed in a suitable arrangement in the process chamber.When the cover has been closed and the program has started, The vacuum is created using a water ring pump. The exhaust air cooler is activated in parallel with switching on the pump(to cool hot process gases) and the catalytic converter is brought up to operating temperature using pre-heated atmospheric air.The process chamber is heated as soon as the catalytic converter has reached its operating temperature. §3. Cleaning stage A.Melting stage During heating up(150℃),the PET materials adhering to the Filter to be cleaned first all become liquid but do not decompose thermally. The melting plastic flows via a discharge trough into the cooler melt container,where it can cool down and then be removed for the further porcessing stage. B.Pyrolysis stage On reaching the decomposition temperature of the respective polymer,the heat output is regulated automatically in the process chamber in such a way that the best possible conversion is guaranteed in the catalytic converter. C.Oxidation stage The oxygen is added to the process chamber to oxidise any remaining residues of the organic products of decomposition.Any remaining inorganic residues on the cleaned components can easily be removed mechanically, D.Cooling stage The process chamber heating is switched off during the cooling stage and the catalytic cleaning of the exhaust gas remains active until the program ends. §4.Technical Parameter ※Power Supply: 380V, 50Hz, total:55KW, Chamber:45KW, Catalytic converter: 6KW, Pump: 4KW ※Average consumption:About 30% electric power ※Water supply: Consumption:~0.4m3/H Water Inlet pressure:0.3-0.6MPa Water inlet temperature:5-30℃ Water intake:RP1” ※Cleaning time: 8-26 hours, (due to the characteristics of the melt and the number of melt on the filter are different, cleaning time is not the same) ※Catalyst converter Temperature range:350-600 Degree Only emit carbon dioxide, water and excess oxygen. ※Explosion relief valve Opening pressure :0.01MPa ※ Water ring vacuum pump Absolute vacuum degree:0.2-0.4bar Power:4KW ※Hydraulic cylinder: To move the cover,1 sets ※N2: pressure:0.3-0.6MPa intake:RP1” ※Control mode: By PLC + touch screen centralized control, process parameters set ※Security measures A. Over temperature alarm: When the temperature exceeds the set temperature of 10℃ (adjustable), and automatically cut off the heating power. B. Alarm for open circuit of thermocouple: When the instrument "PV" display (UUUU), and automatically cut off the heating power. C. Without water, low water pressure alarm (sound and light): By the pressure relay, detect the water pressure when the water or the water pressure is lower than the set value, automatically stop working vacuum pump, and automatically cut off the power. D. Over-pressure alarm (sound and light):When the pressure exceeds 0.01Mpa, automatically open the explosion relief valve, and cut off all the heating power . Open the nitrogen valve and close the nitrogen valve to the furnace in 5 minutes. E. Vacuum pump does not run or vacuum pump in the process of vacuum is lower than the lower limit of -0.035MPa, equipment alarm, while cut off the heating power within "1 minutes", and at the same time opening the explosion relief valve, to protect. F. Furnace heating in a period of time did not reach the set value, the equipment alarm, while cut off the heating power within 1 minutes, meanwhile opening the explosion relief valve, to protect Out Of Device  |